Precision Machining

We Provide Precision Machining

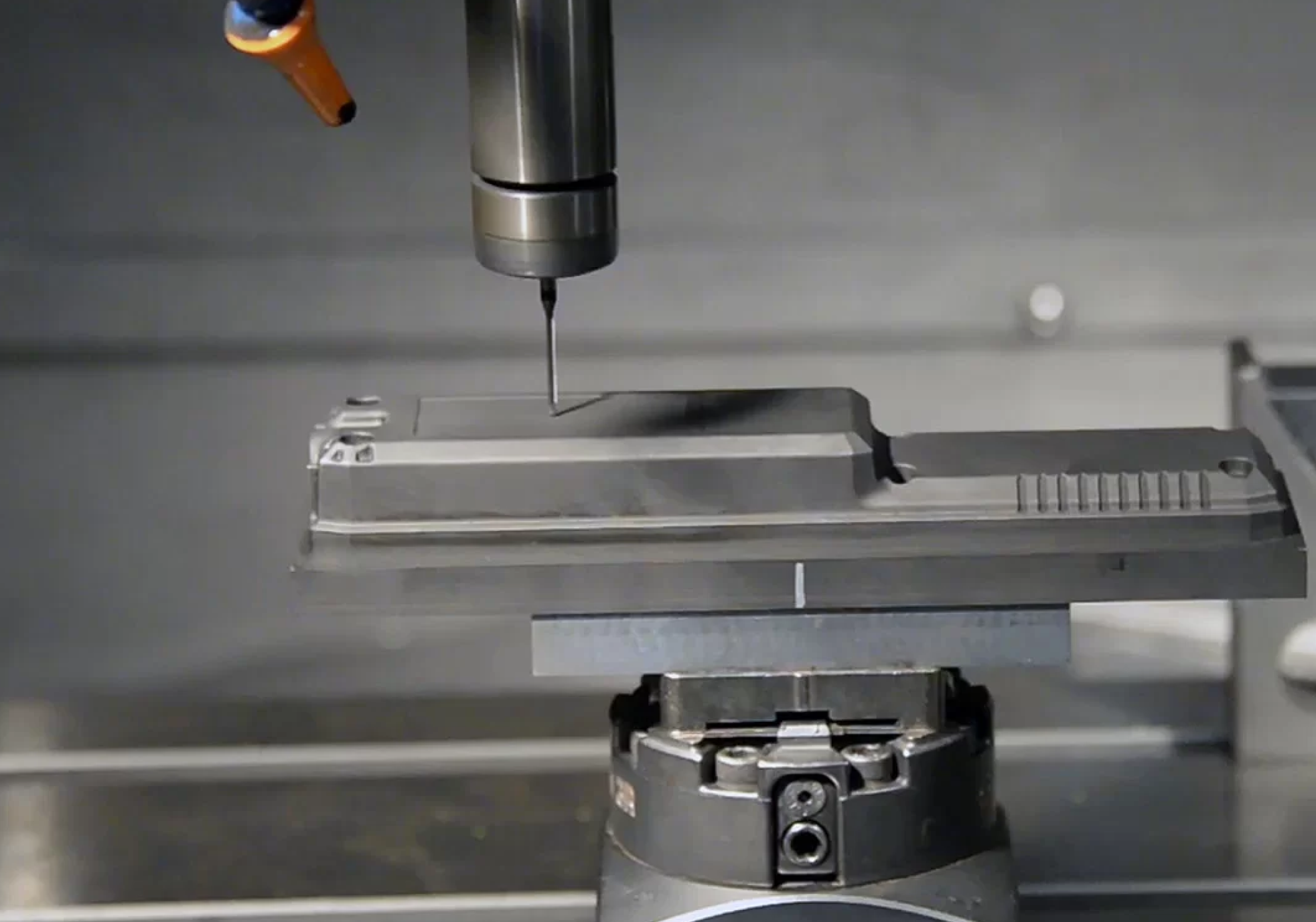

Precision machining is achieved through a powerful combination of digital technologies and traditional machining equipment. We use a mix of 3D CAD/CAM software, CNC equipment, and digital integration methods to achieve precision in intricate parts.

By using 3D CAD/CAM software and CNC equipment, along with advanced techniques like EDM, Prime Manufacturing Technologies achieves exceptional precision, efficiency, and repeatability in the production of complex and intricate parts. Our proven process provides rapid, cost effective turnaround of tools and parts.

How Our Technology Works Together

3D CAD/CAM Software

- Design and Modeling – The process starts with creating a precise 3D model of the desired part using computer-aided design (CAD) software. This software allows engineers to define the part’s geometry, dimensions, and tolerances in minute detail.

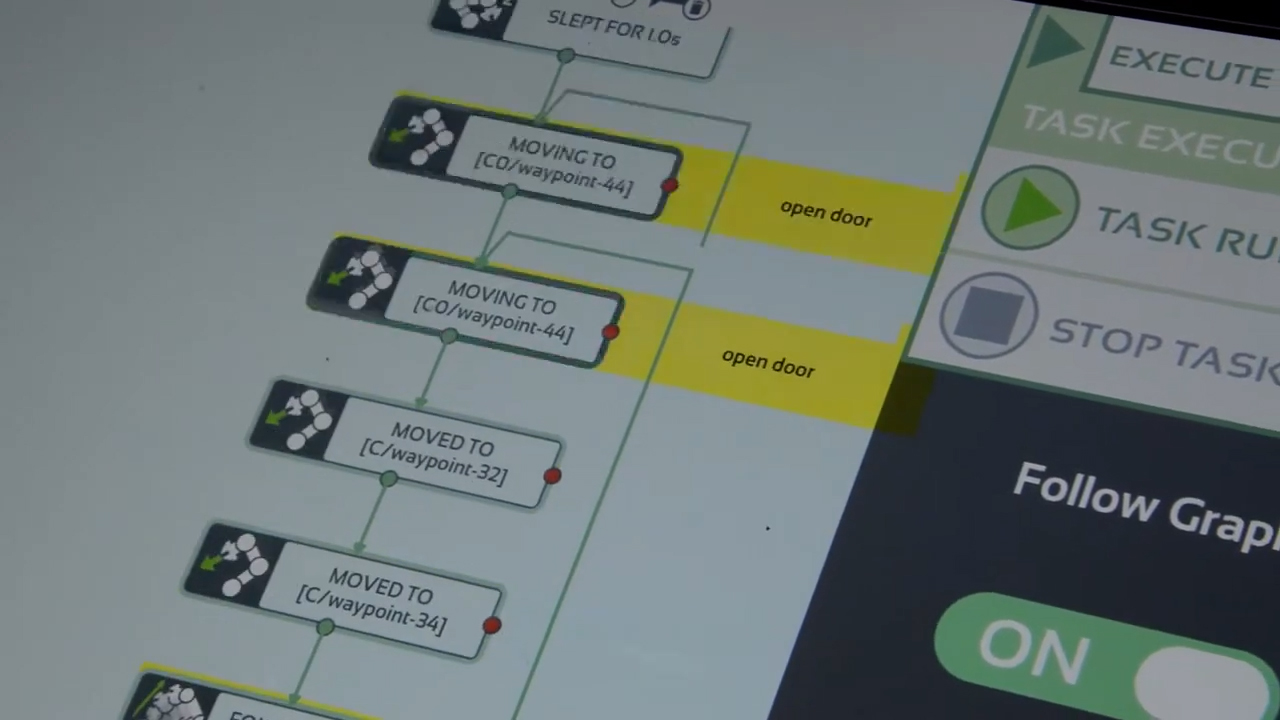

- Toolpath Generation – Once the 3D model is complete, computer-aided manufacturing (CAM) software takes over. It analyzes the model and generates precise instructions (toolpaths) for the CNC machine to follow. These toolpaths control the movement and actions of the cutting tool to remove material from the workpiece and achieve the final shape.

- Simulation and Optimization – Modern CAM software allows simulating the machining process virtually. This helps identify potential issues like collisions or inefficiencies in the toolpath and refine them for optimal results.

CNC Equipment

- CNC (Computer Numerical Control) – This refers to the computer control system that governs the CNC machine. It receives the toolpath instructions from the CAM software and translates them into precise movements of the machine’s axes and cutting tools.

- Lathes and Mills – These are the workhorses of precision machining. CNC lathes are ideal for creating cylindrical or rotationally symmetrical parts, while CNC mills handle more complex 3D geometries with flat surfaces, angles, and pockets.

- Electrical Discharge Machining (EDM) – This specialized technique uses controlled electrical sparks to erode material from the workpiece. EDM is particularly valuable for creating intricate shapes or features in very hard materials that would be difficult to machine with traditional cutting tools.

Digital Manufacturing Integration

- Seamless Workflow – 3D CAD/CAM software often integrates seamlessly with CNC controls, enabling a smooth flow of data from design to manufacturing. This eliminates the need for manual programming and reduces errors.

- Precision and Repeatability – The digital control offered by CNC and CAM software ensures exceptional precision and repeatability in the machining process. Parts are consistently produced within the specified tolerances, leading to high-quality results.

- Flexibility and Automation – Digital manufacturing allows for quick turnaround times, as changes to the design can be reflected in the toolpath almost instantly. Additionally, CNC machines can operate with minimal human intervention, leading to increased efficiency and automation in production.