Plastic Injection Molding

Plastic Injection Molding is a Cost-Effective Solution

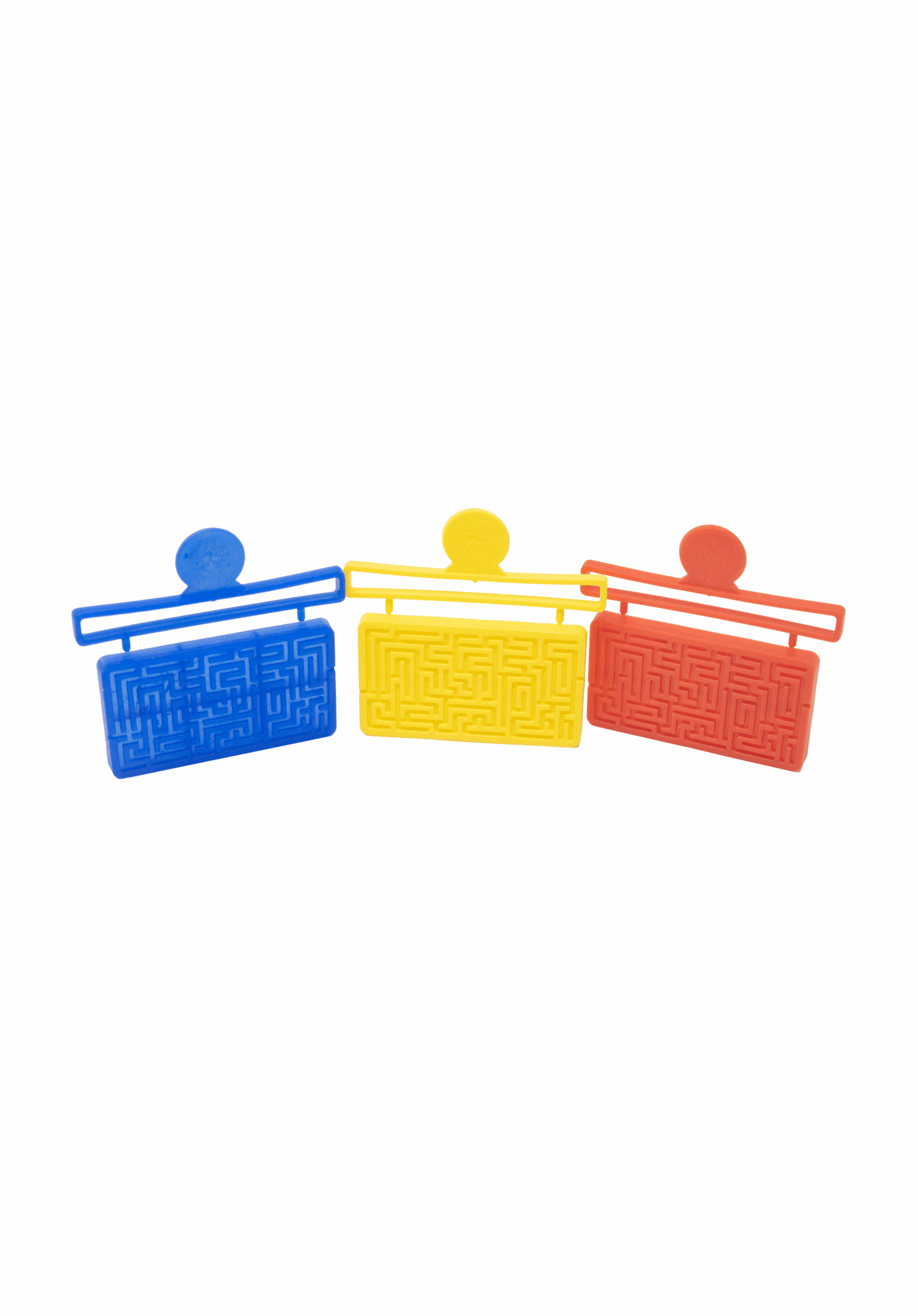

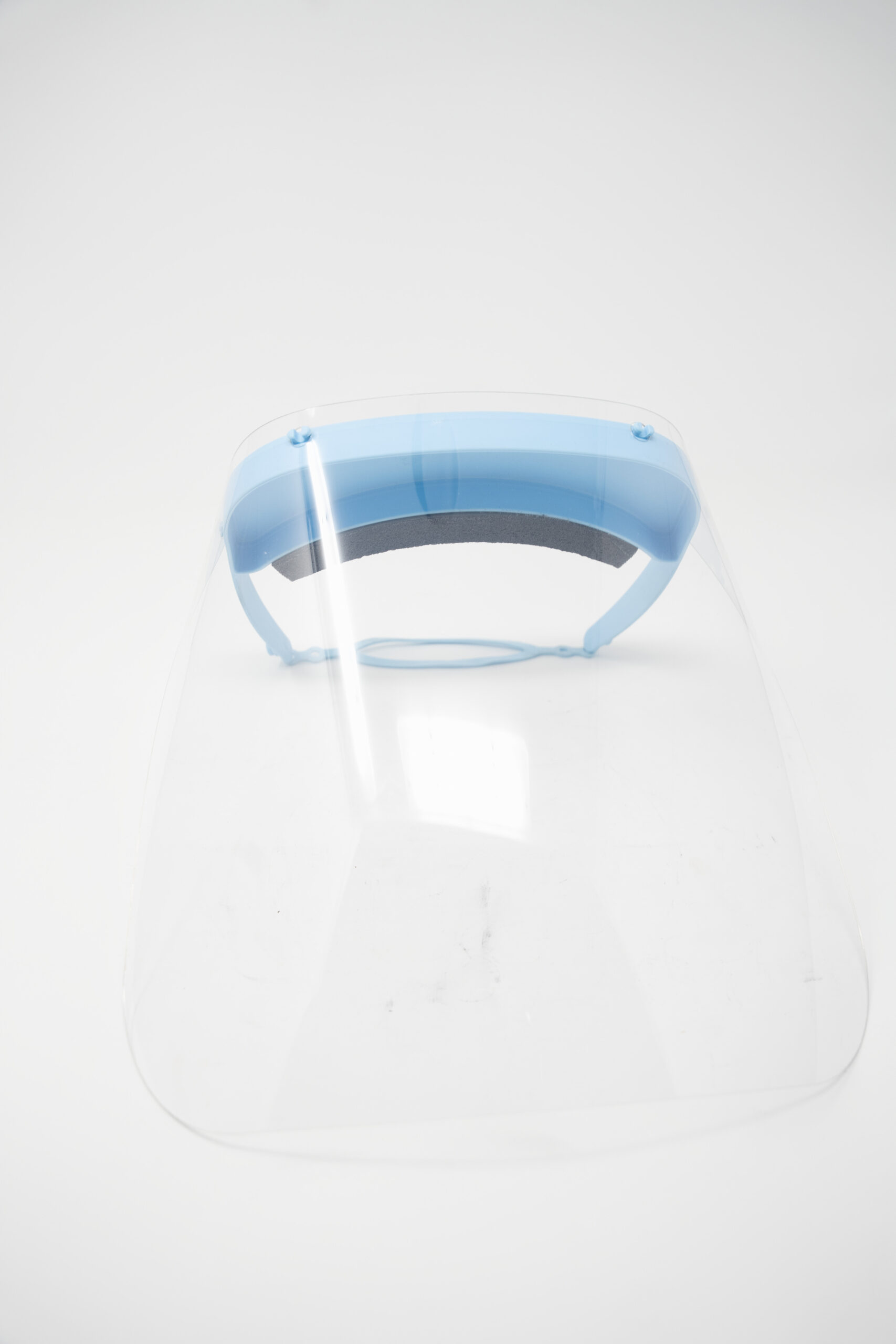

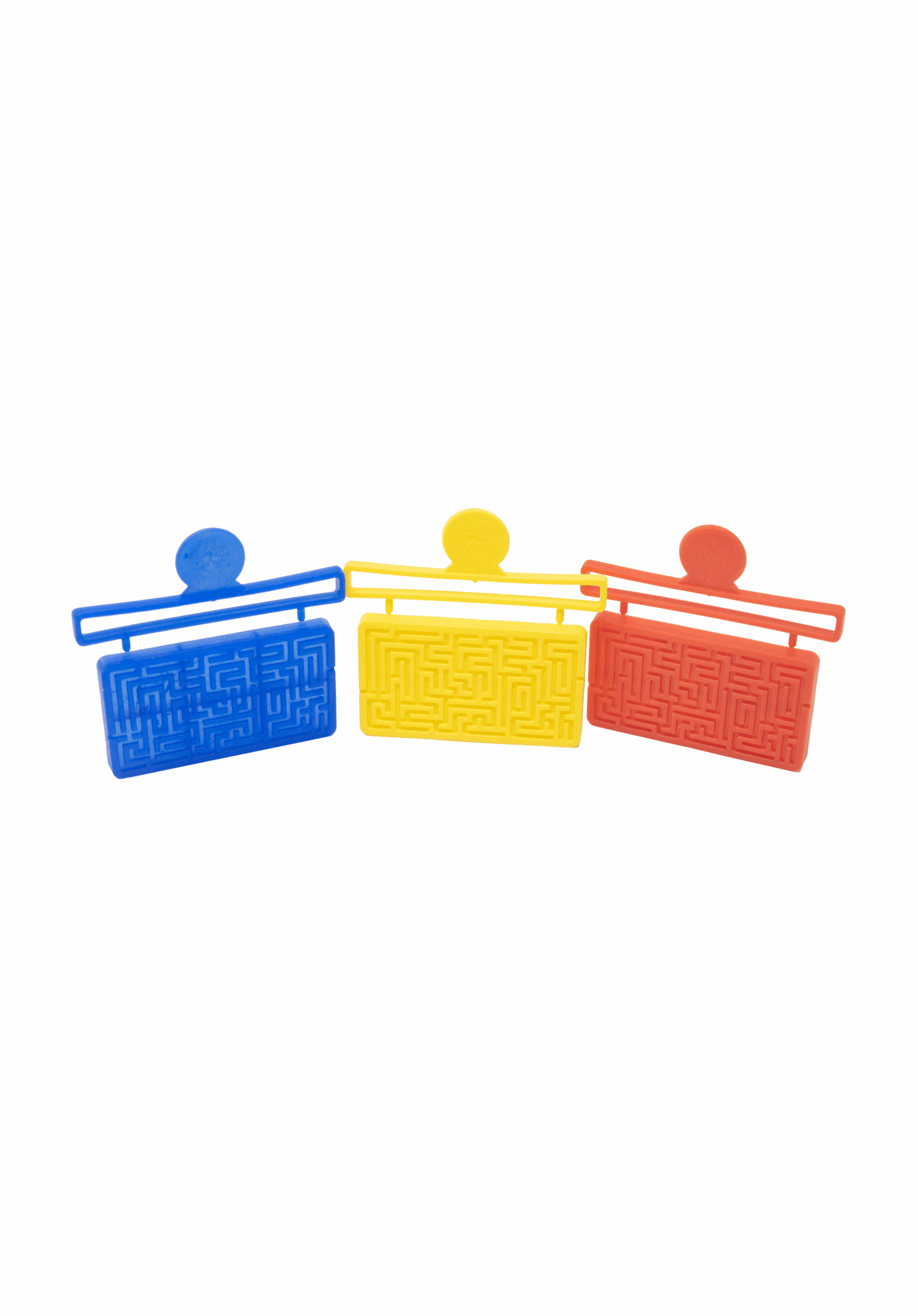

Prime Manufacturing Technologies are experts in plastic injection molding, a widely used and versatile manufacturing process for creating plastic parts in high volumes. We mold all thermoplastics and engineered plastics, including elastomeric thermoplastic rubbers.

We start with a digital CAD model of the part, followed by CAD mold design and mold making by computerized equipment. The completed mold is then mounted on the molding machine and the desired material is then injected into the mold to produce the desired part. Our all-electric servo-driven molding machines ensure the production of accurate, precision parts.

Potential Industry Applications

At Prime Manufacturing Technologies, we use plastic injection molding to create a vast array of products and parts. This is a highly adaptable process and is currently used across a wide array of industries, including:

Consumer Electronics – Phone cases, keyboards, and various internal components.

Household Products – Storage containers, toys, appliance parts.

Automotive – Interior parts, dashboards, bumpers, and other components.

Packaging – Bottles, containers, caps, and closures.

Medical Devices – Syringe bodies, housings for medical instruments.

Our Step-by-Step Process

-

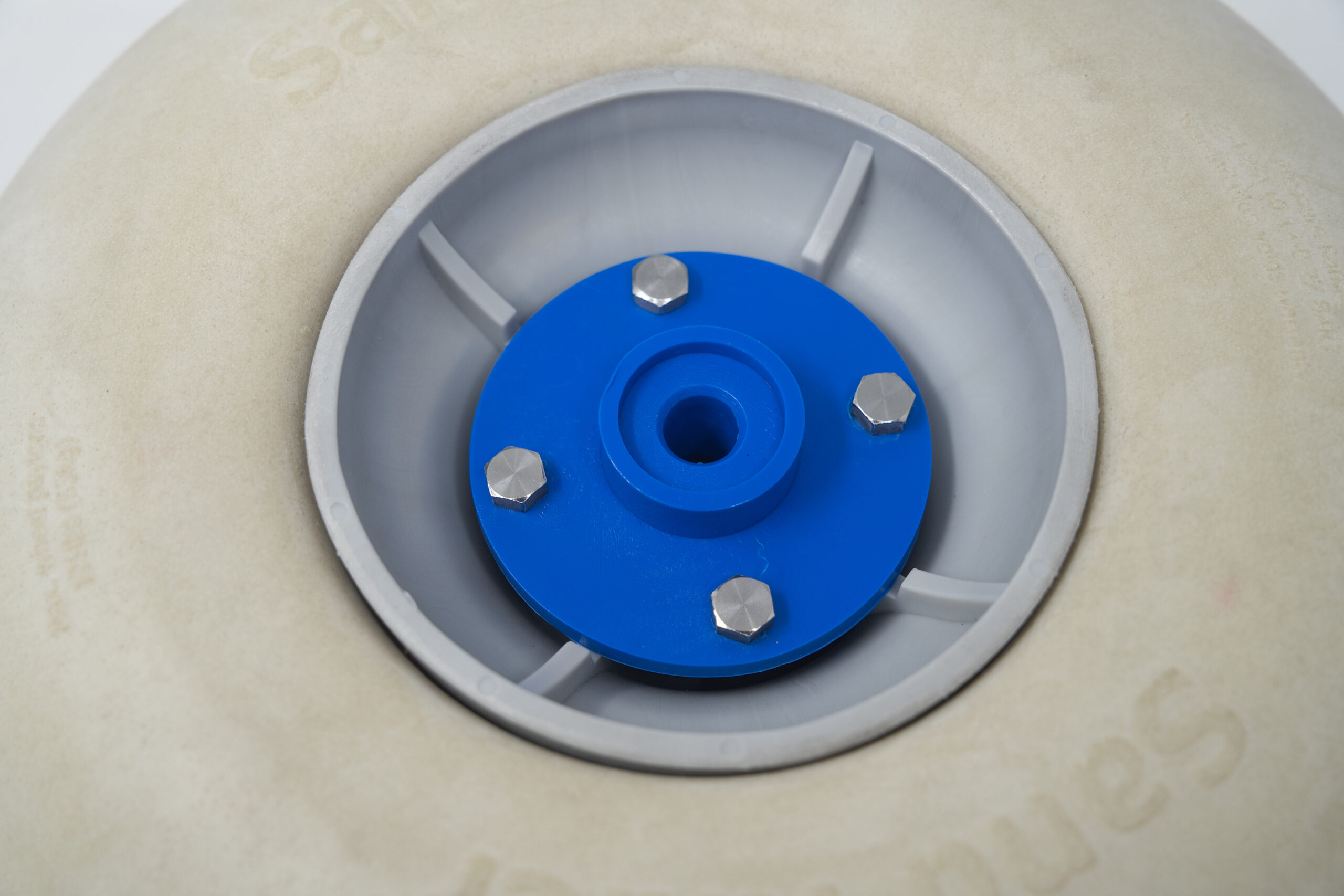

Mold Creation

A specialized metal mold is designed and built with the desired shape of the final product. This mold typically consists of two halves that clamp together. -

Material Preparation

Plastic resin pellets are fed into a hopper on the injection molding machine. -

Melting and Injection

The pellets are heated and melted inside the machine’s barrel. Once molten, a screw mechanism pushes the plastic into the mold cavity under high pressure. -

Cooling and Ejection

The plastic cools and solidifies within the mold cavity, taking the shape of the mold. Once cooled, the mold opens, and the finished part is ejected. -

Finishing Touches

Depending on the application, parts may undergo additional processes like trimming, de-flashing (removing excess plastic), or surface finishing.

Major Benefits of Plastic Injection Molding

High Production Rates

This process allows for rapid and consistent production of identical parts, ideal for mass production.

Cost-Effectiveness

For high-volume production, injection molding becomes very cost-effective, especially with minimal material waste.

Design Versatility

Molds can be designed to create complex shapes with high precision and detail.

Repeatability

The process ensures consistent quality and dimensional accuracy across large quantities of parts.

Material Options

A wide range of plastic materials can be used, catering to various properties like strength, flexibility, and heat resistance.

Scalability

Production volume can be easily adjusted by modifying machine parameters or adding additional machines.Gallery