Metal Injection Molding

Metal Injection Molding is a Flexible, Cost-Effective Solution

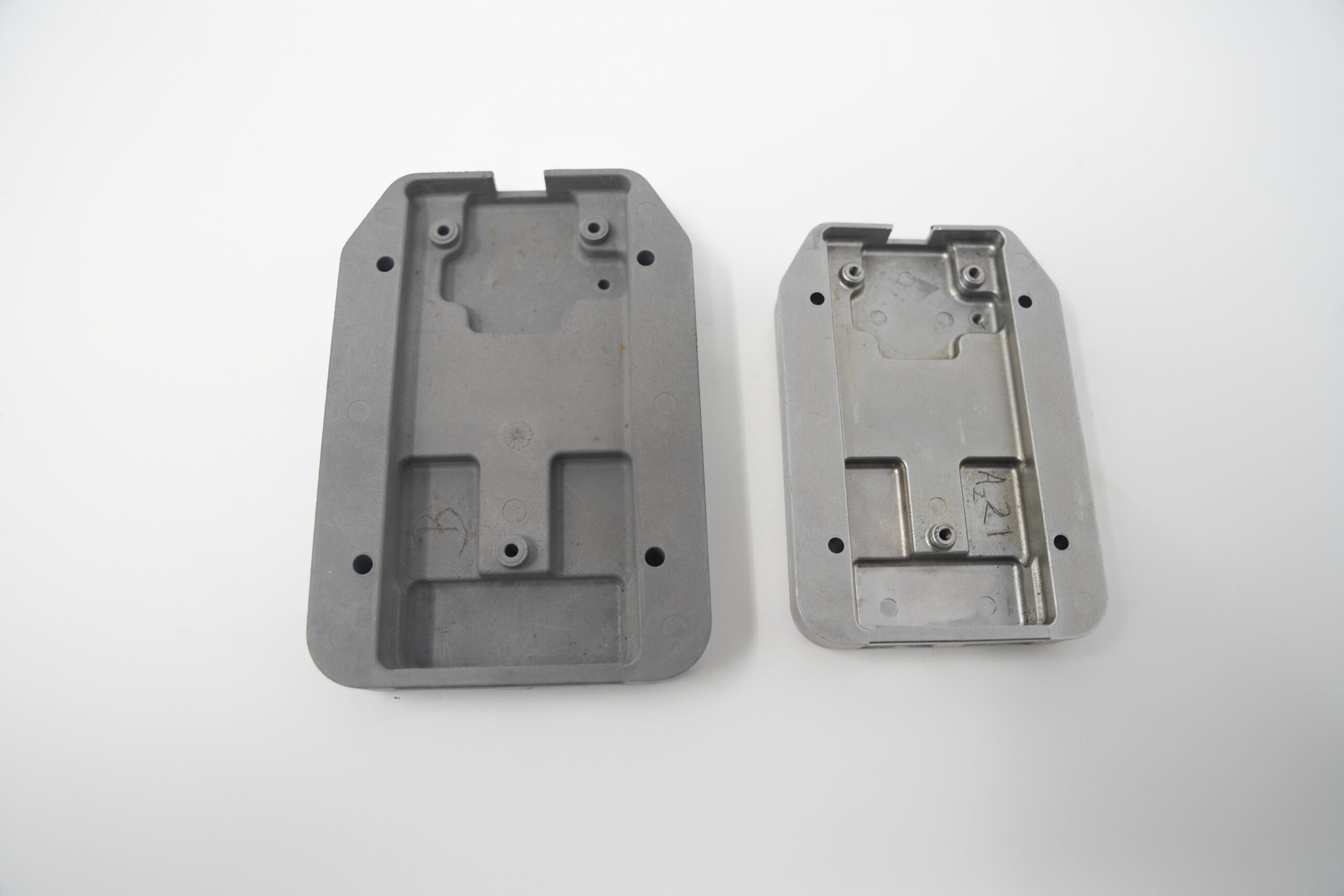

Metal injection molding (MIM) is a unique manufacturing process that combines aspects of plastic injection molding and metalworking to create complex and precise metal parts. This also enables the manufacturing of intricate metal parts at high volumes. At Prime Manufacturing Technologies, we can mold stainless steel parts to net shape. Other ferrous and ceramic materials can also be molded with this process.

Potential Industry Applications

Metal Injection Molding is perfect for creating small, intricate metal parts with complex geometries that are expensive and often challenging to produce through traditional methods like machining or casting. Here are some major industries that can benefit from the metal injection molding process:

Automotive – Gears, engine components, fuel system parts, and other high-precision components.

Consumer Electronics – Housings for electronic devices, heat sinks, and thermal management components.

Medical/Dental – Implants, surgical instruments, and dental crowns and bridges.

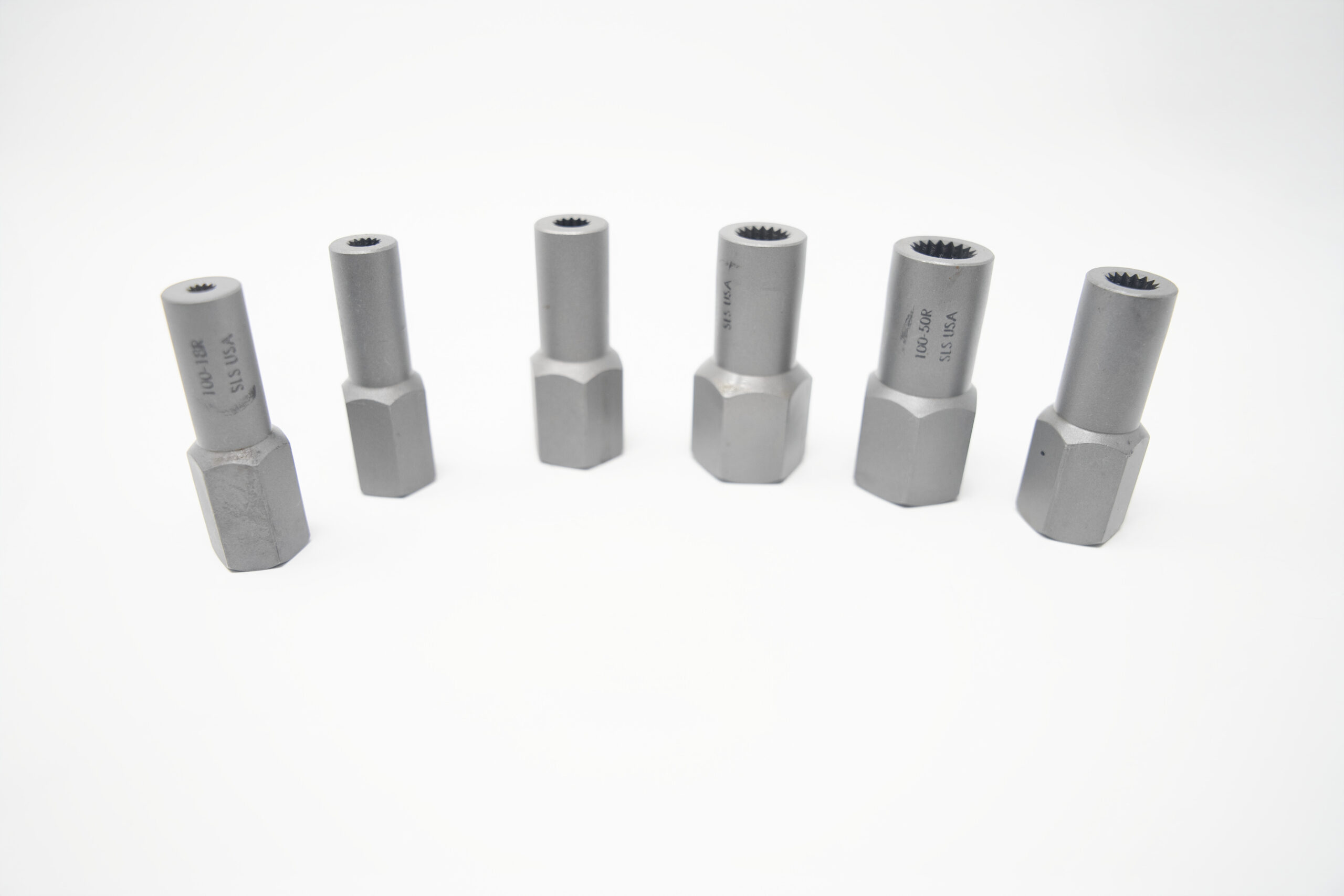

Aerospace and Defense – Parts for aircraft engines, firearms components, and other high-performance applications.

Industrial Equipment – Fasteners, gears, and other intricate components for various machinery.

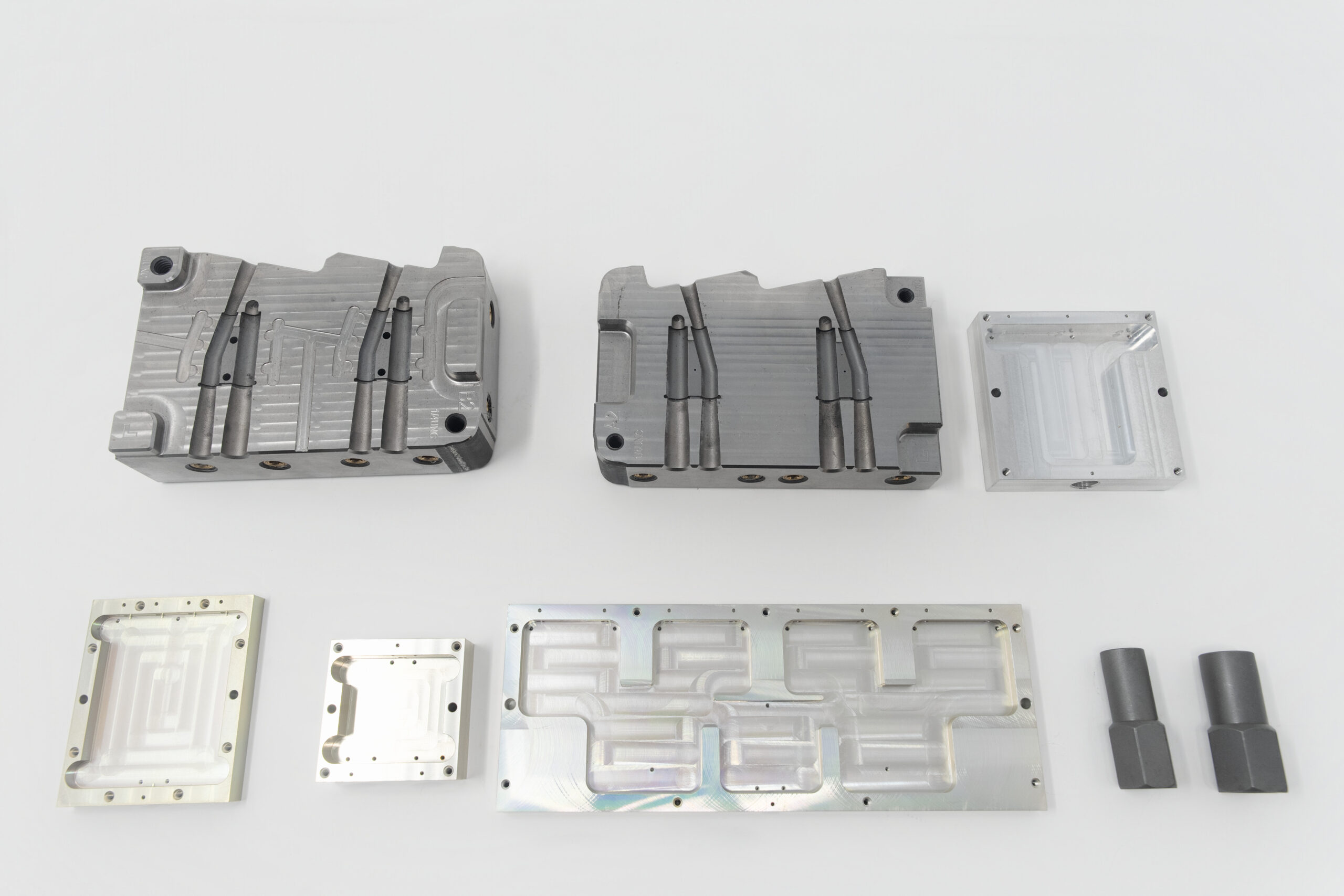

Our Step-by-Step Process

-

Feedstock Preparation

Metal powder (usually very fine) is mixed with a binder material to create a moldable paste-like substance called feedstock. The binder helps the metal particles hold their shape during molding. -

Mold Creation

Metal powder (usually very fine) is mixed with a binder material to create a moldable paste-like substance called feedstock. The binder helps the metal particles hold their shape during molding. -

Debinding

The binder is removed through a controlled heating process, leaving behind a fragile metal shape. This can involve solvent leaching, thermal decomposition, or catalytic debinding. -

Sintering

The debindered metal part is then subjected to high temperatures in a furnace, causing the metal particles to fuse together and shrink slightly, resulting in a strong and dense final metal component. -

Final Adjustments

Depending on the application, parts may undergo additional processes like machining, polishing, or heat treatment for specific functionalities.

Major Benefits of Plastic Injection Molding

Complex Geometries

Metal injection molding excels at producing intricate shapes with tight tolerances, ideal for parts with internal features or thin walls.

Cost-Effectiveness

For high-volume production, injection molding becomes very cost-effective, especially with minimal material waste.

High Production Rates

This process allows for rapid and consistent production of identical parts, ideal for mass production.

Design Flexibility

Using molds frees up the design process, allowing the incorporation of features like threads, undercuts, and surface textures directly into the parts.

Material Options

A wide range of plastic materials can be used, catering to various properties like strength, flexibility, and heat resistance.

Near-Net Shapes

Metal injection molding requires minimal post-processing saving time and material.Gallery