High-Speed Inspections

High-Speed Inspections are a Critical Process in Modern Manufacturing

High-speed inspection is constantly evolving with advancements in imaging technology, processing power, and AI. It plays a vital role in ensuring the quality and reliability of manufactured products across various industries while ensuring proper quality control and efficiency for your parts.

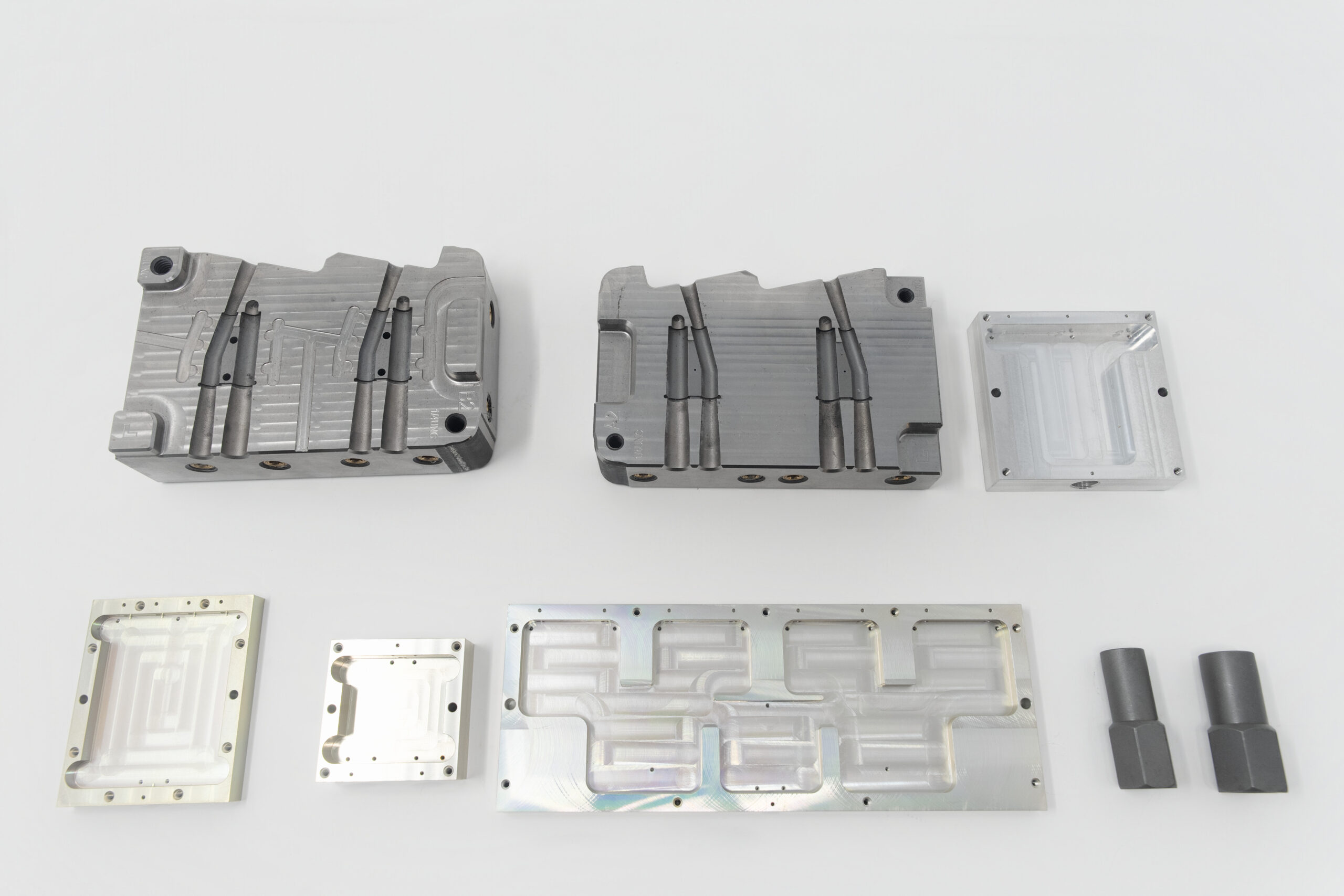

High-speed parts inspections in manufacturing use automated systems like vision, laser, or X-ray to rapidly check for defects or dimensional inaccuracies. This can involve real-time analysis, integration with production lines, and ensuring product quality without slowing down the rate of output. To get the best results from your inspection, we will determine which systems and methods are optimal for inspecting the parts. Some of these factors are the specific flaws you want to detect, the rate of production, and how the material interacts with the advanced imaging technology.

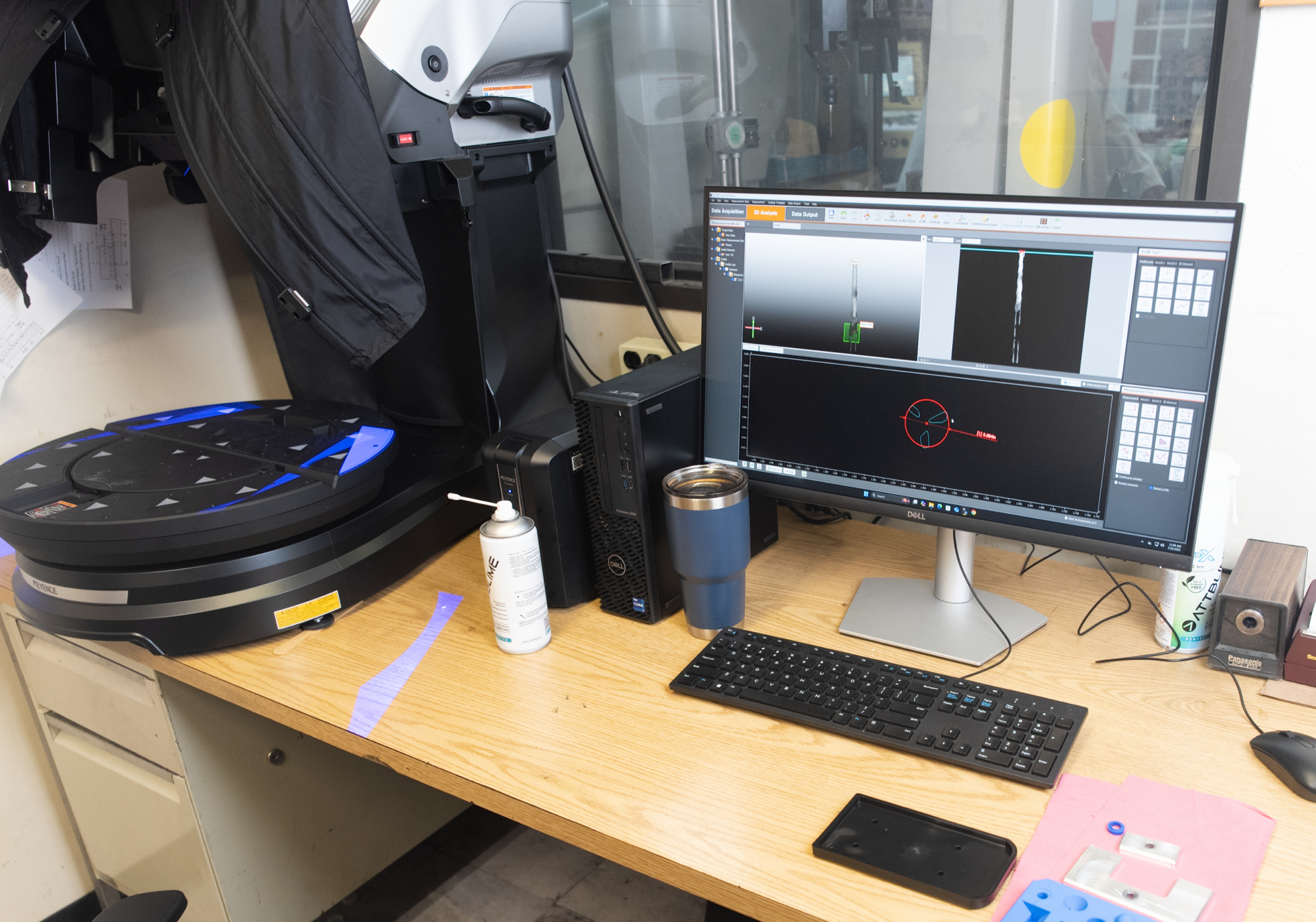

Advanced Imaging Technologies

Machine Vision – Cameras and sensors capture images of parts at high speeds. These images are then processed and analyzed by specialized software to identify defects.

3D Imaging – For complex shapes, 3D imaging provides a more complete picture, allowing for precise measurement and defect detection.

Line Scan Cameras – These cameras capture images one line at a time, ideal for inspecting parts moving on a conveyor belt.

Hyperspectral Imaging – This technique captures images across a wide range of wavelengths, revealing subtle defects invisible to the naked eye.

Types of Defects We Can Detect

- Dimensional inaccuracies – Variations in size, shape, or position.

- Surface defects – Scratches, dents, cracks, or discoloration.

- Missing or damaged components – Ensuring all parts are present and in good condition.

- Functional defects – Testing for proper operation and performance.

Automated Material Handling

- Robotics – Robots are often used to handle parts, precisely positioning them for inspection and sorting them based on the results.

- Conveyors – High-speed conveyors move parts through the inspection system quickly and efficiently.

Potential Industry Applications

Automotive – Inspecting parts for safety and quality.

Electronics – Ensuring the integrity of circuit boards and components.

Pharmaceuticals – Verifying the quality and consistency of medications.

Food and Beverage – Detecting contaminants and ensuring product safety.

Packaging – Checking for proper sealing and labeling.

Major Benefits of Conducting Inspections

Increased Production Efficiency

Faster inspection speeds keep pace with high-volume manufacturing.

Enhanced Safety

Automated systems can handle hazardous materials or environments.

Improved Quality Control

Early defect detection reduces waste and rework.

Data-Driven Insights

Inspection data can be used to improve processes and prevent future defects.