About Precision Plastics

About Our CEO

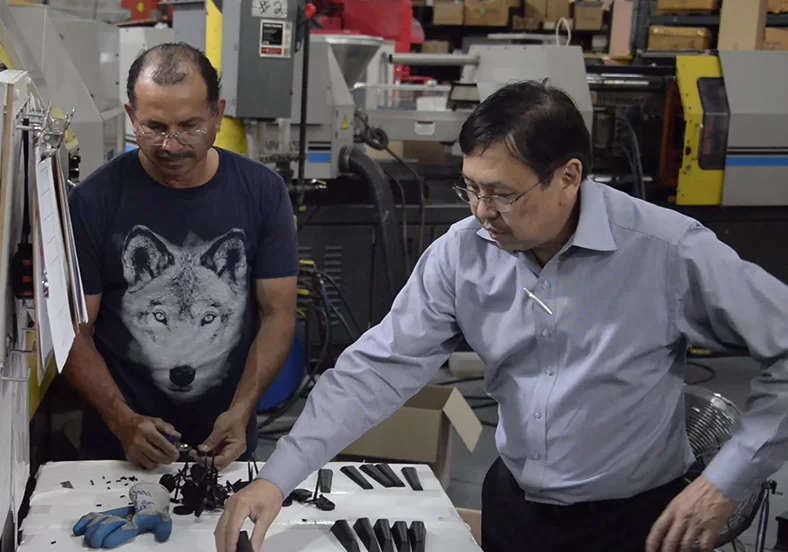

Luke Chow Is president and CEO of Prime Manufacturing Technologies, Inc. A Chemical Engineer by training from the University of Pennsylvania in Philadelphia, Luke held research and development and engineering positions with Allied Corporation, a major American company with operations in the chemical, aerospace, automotive, oil and gas industries.

After a successful career in corporate America, Luke decided it was time to test his entrepreneurial leanings. He moved from Pennsylvania to Maryland in 1991, where he started Prime Manufacturing Technologies. He focused the young company on plastic injection molding, composites and CNC machining, with an emphasis on lean and agile manufacturing processes. During his 27 years of incomparable leadership, Prime has earned a reputation for quality and attention to detail.

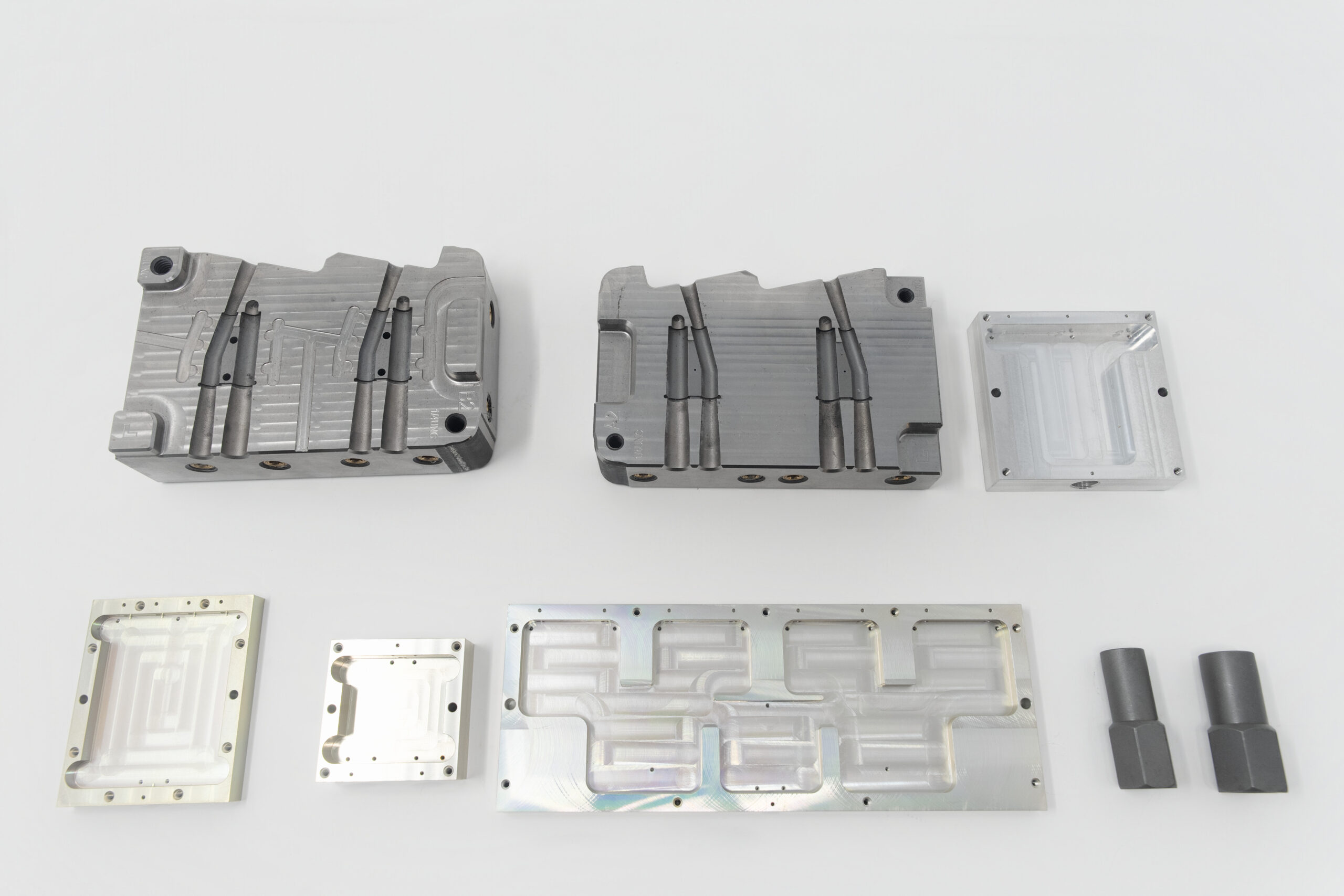

Rapid tooling and prototyping had always been on Luke’s “radar.” He was an early adopter of 3D printing in the mid 90’s, following it evolution and adding it to Prime’s expanding technology skillset, keeping the company on the cutting edge of manufacturing.

Leadership & Company Profile

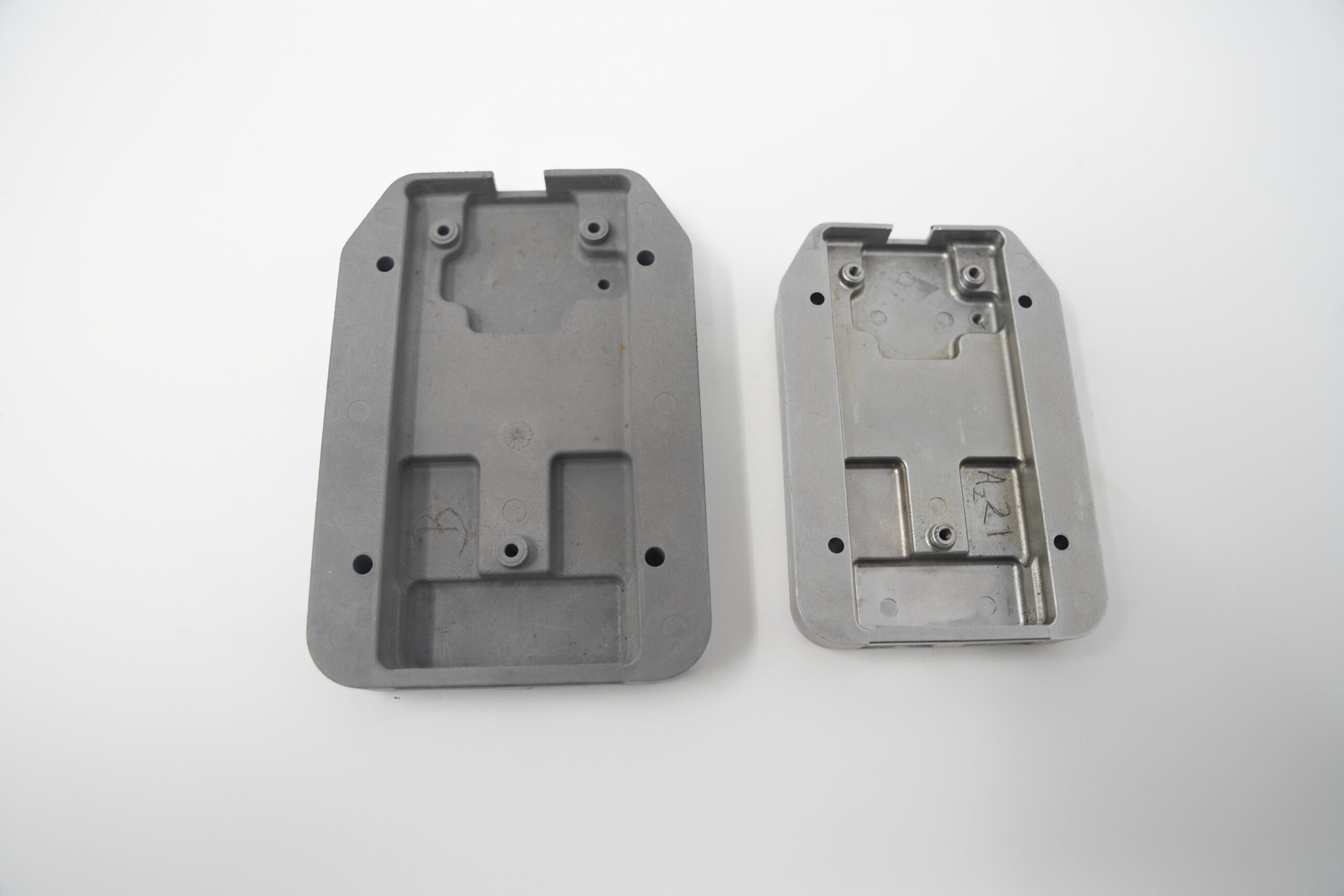

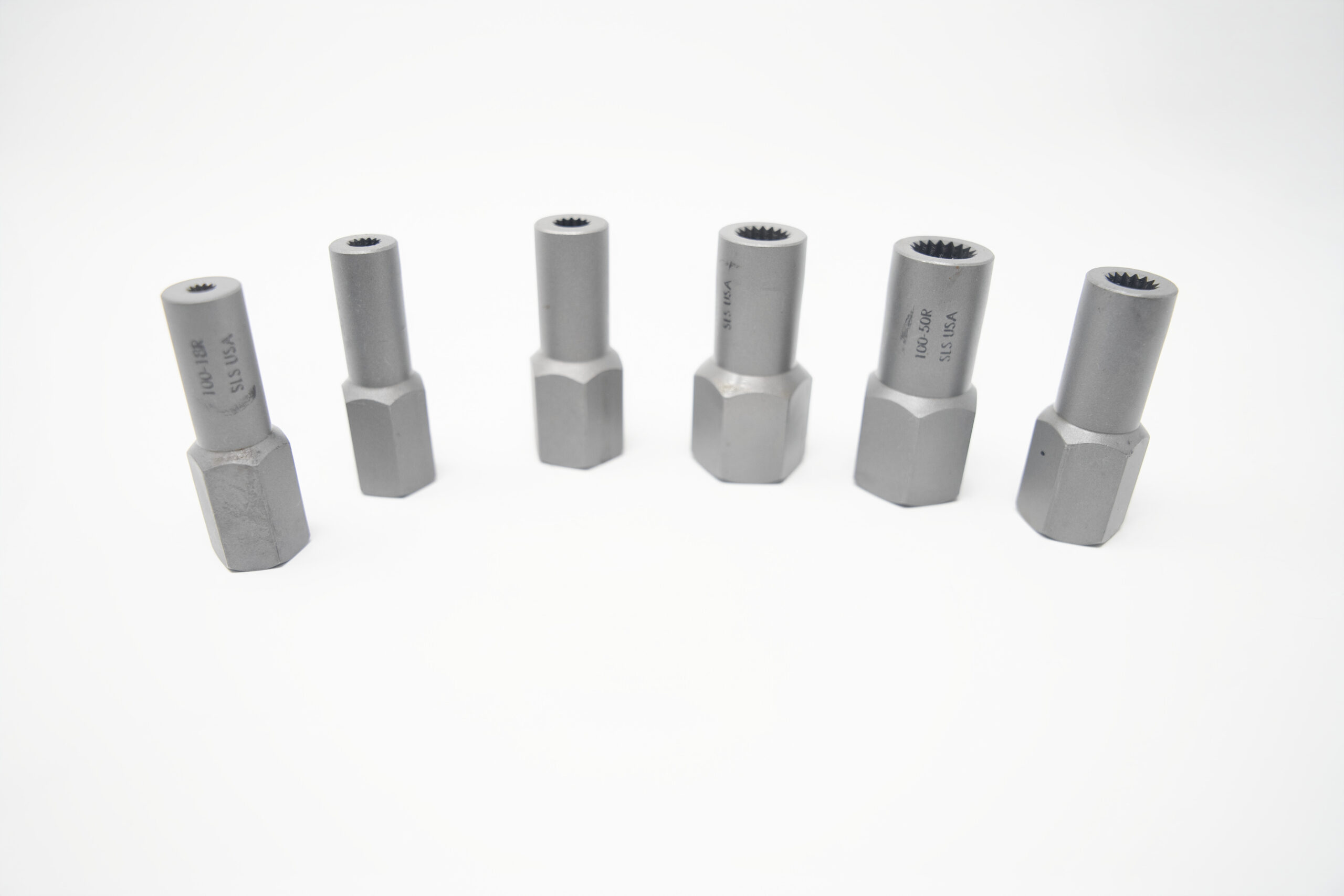

For over 27 years, Prime Manufacturing Technologies, Inc. has offered cost-effective, innovative manufacturing alternatives, geared to streamlining and improving customer product needs. Based in Savage, Maryland, Prime manufactures plastic, metal and composite products, parts and sub-assemblies for commercial, industrial and military applications.

As part of its mission, Prime recognizes that practicing lean manufacturing is not enough. The company believes that a great manufacturing system also needs to be agile and designed for rapid response.

Prime’s primary goal is to offer great value for its services, with an emphasis on quality, on-time delivery and exceptional customer service. The entire Prime team works diligently and systematically to bring the most flexible and cost-effective manufacturing alternatives to its clients.

Unparalleled Experience

The Prime team of certified, degreed and trained personnel are experienced industry veterans, all ready to support your manufacturing project with a commitment to getting the job done on time and on budget. Exceeding customer expectations is always or priority.

We strive to provide an exceptional manufacturing experience featuring a unique breadth of capabilities ready for deployment to provide lasting manufacturing solutions, or to support your maintenance department with new or refurbished parts and components.

Prime uses a unique mix of manual technology with robotics and automation. This approach offers a more cost-effective process, giving customers the best value for their product initiatives. Many times, Prime’s engineering and technical strengths have been called upon to assist in solving major manufacturing problems, value engineering and cost reduction projects. They have earned a reputation for recommending the most appropriate manufacturing technologies, deploying concurrent engineering when needed to achieve substantial financial and time savings for customers.

Gallery