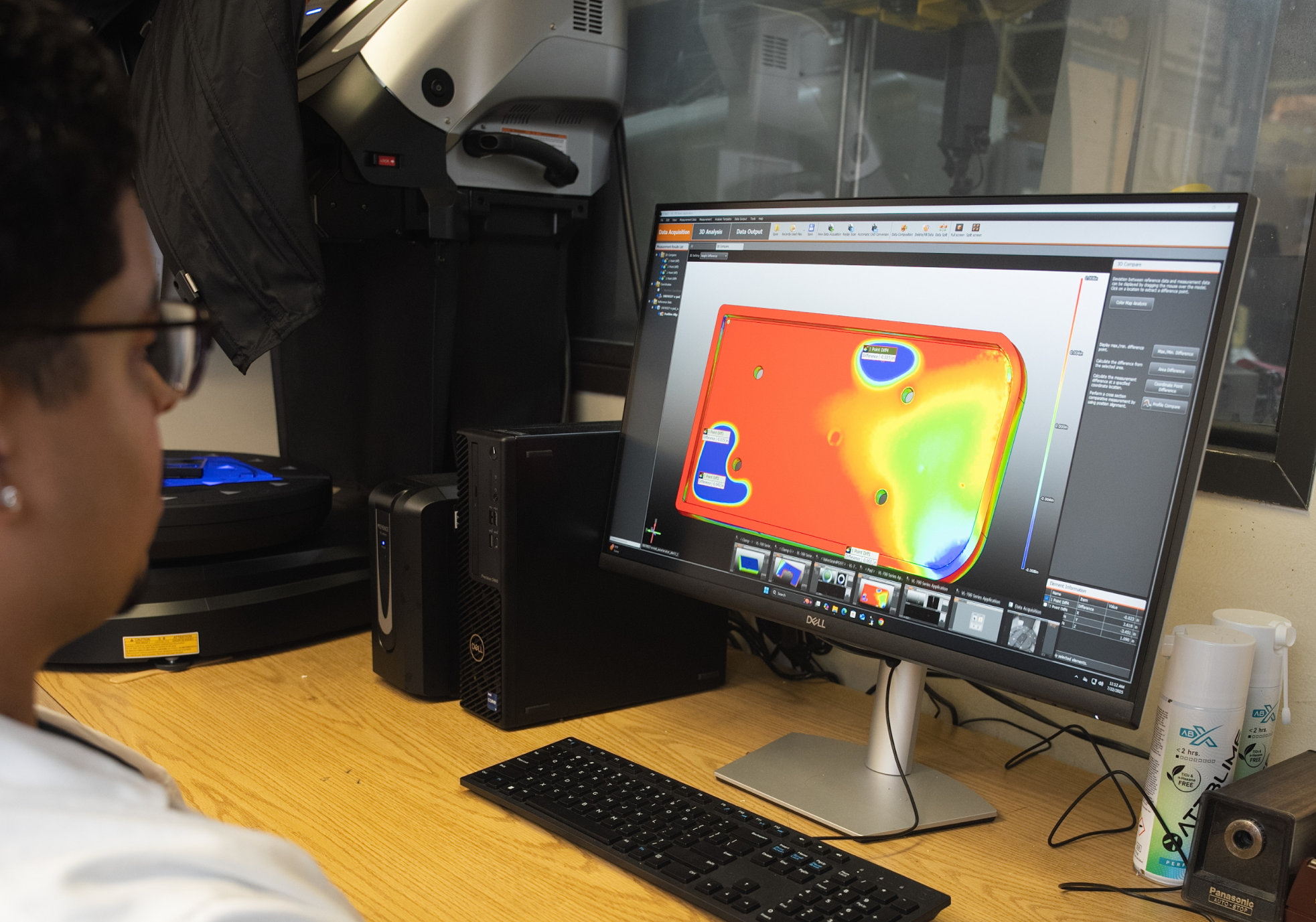

3D Scanning

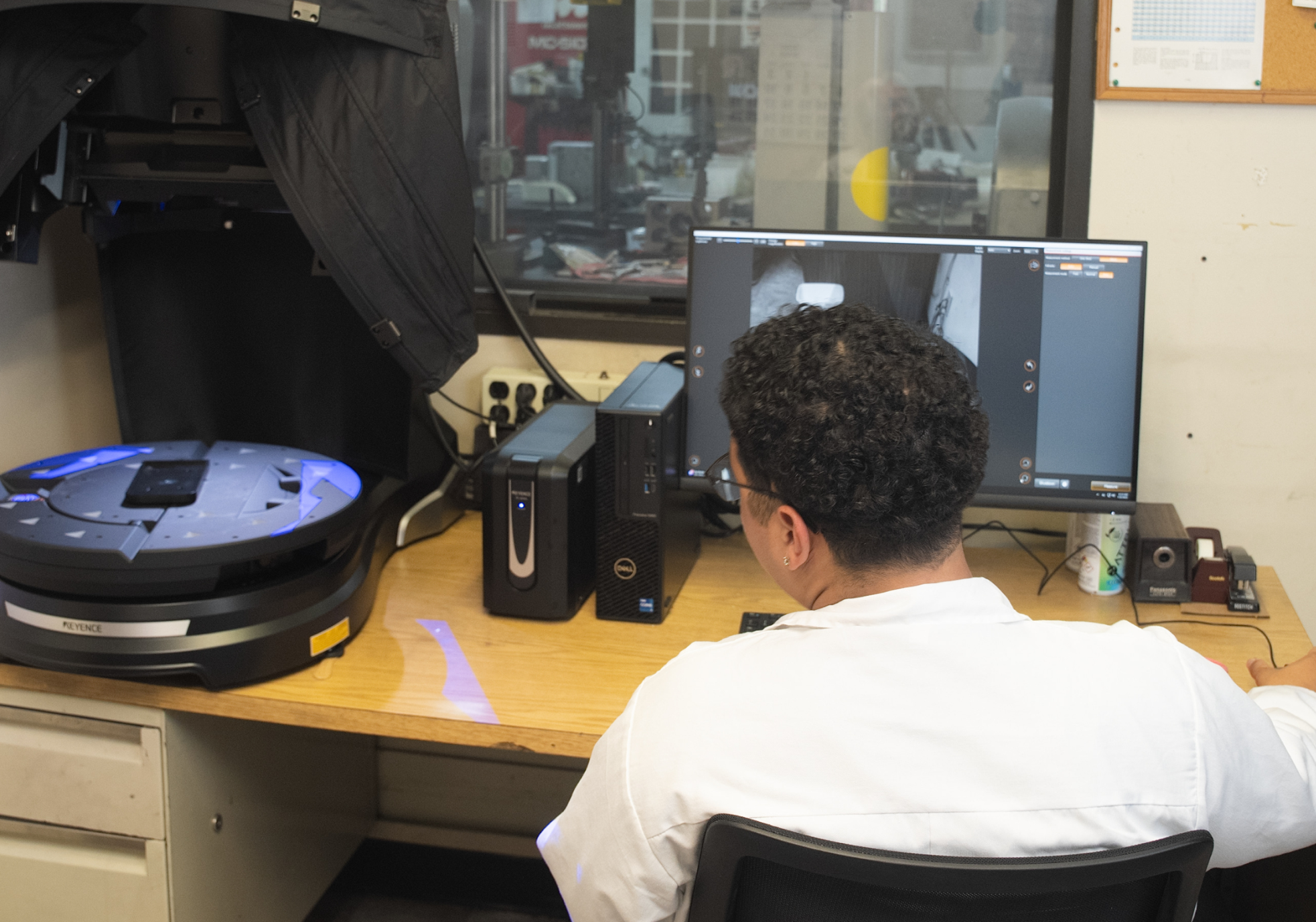

We use Advanced 3D Scanning Technology

Our 3D scanning provides a precise and efficient method for capturing physical objects and translating them into digital spaces. Using updated 3D scanning technology can help reduce manufacturing costs while increasing the quality and integrity of your parts. The process analyzes an object and creates data points to construct digital 3D models. The adoption of 3D scanning has overcome some limitations of traditional measurement techniques offering speed, accuracy, and details with less investment. 3D scanning has lead to easier manufacturing processing, quality control, and advancing reverse engineering. It bridges the gap between physical and digital domains with enhanced analysis, design, and manipulation of real world objects in a virtual space.

3D Scanning Streamlines the Design-to-Product Journey

Our 3D Scanning relies on a variety of technologies dependent on the type of object being scanned. Generally, patterns of light are projected onto the object to create a grid-like structure. The surface of the object obstructs the grid-like pattern by reflecting or distorting the light. A sensor is used to detect these obstructions and creates data points. A program analyzes these data points to determine size, shape, and structure of the object. Using this analysis and digital 3d model can be made.

Digital Archiving & Reverse Engineering

Assembly Verification

Damage Assessment & Quality Control

Rapid Prototyping & Design Optimization

Our 3D Scanning Technology

Creation and Understanding of Digital Assets

- Higher Resolution Scanners – New scanners capture incredibly detailed 3D data, enabling more accurate measurements and the detection of even minor flaws. This leads to higher quality products and less waste due to defects.

- Improved Accuracy in Challenging Environments – Advancements in laser and structured light scanning allow for accurate scanning of shiny, reflective, or complex surfaces that were previously difficult to capture.

- AI-Powered Defect Detection – Artificial intelligence and machine learning algorithms are being used to analyze 3D scan data, automatically identifying defects and anomalies with greater accuracy.

- Cloud-Based Processing – Cloud computing enables faster processing and analysis of large 3D datasets, making it easier to manage and share scan data.

- AI-Powered Defect Detection – Artificial intelligence and machine learning algorithms are being used to analyze 3D scan data, automatically identifying defects and anomalies with greater accuracy.

- Cloud-Based Processing – Cloud computing enables faster processing and analysis of large 3D datasets, making it easier to manage and share scan data.

Analysis and Verification Using Digital Data

- Robotic Integration – 3D scanners are being integrated with robots for automated inspection and quality control. This reduces the need for manual inspection and improves consistency.

- Inline Inspection – Scanners can be incorporated directly into production lines for continuous inspection and real-time process monitoring.

- Additive Manufacturing – 3D scanning is crucial for generating accurate models for 3D printing, enabling the creation of complex and customized parts.

- Reverse Engineering – Quickly capturing the geometry of existing parts allows for faster and more accurate reverse engineering, facilitating product improvement and legacy part recreation.

- Virtual and Augmented Reality – 3D scan data can be used to create immersive VR and AR experiences for design review, training, and maintenance.

Major Benefits of 3D Scanning

Improved Product Quality

More accurate scanning leads to fewer defects and higher quality products.

Greater Innovations

3D scanning enables the creation of more complex and customized products.

Increased Efficiency

Faster scanning and automated processes reduce lead times and improve productivity.

Enhanced Collaboration

Digital 3D models facilitate better communication and collaboration among design and manufacturing teams.