Design, Manufacturing, and Production Solutions

One Stop Digital Manufacturing Solution

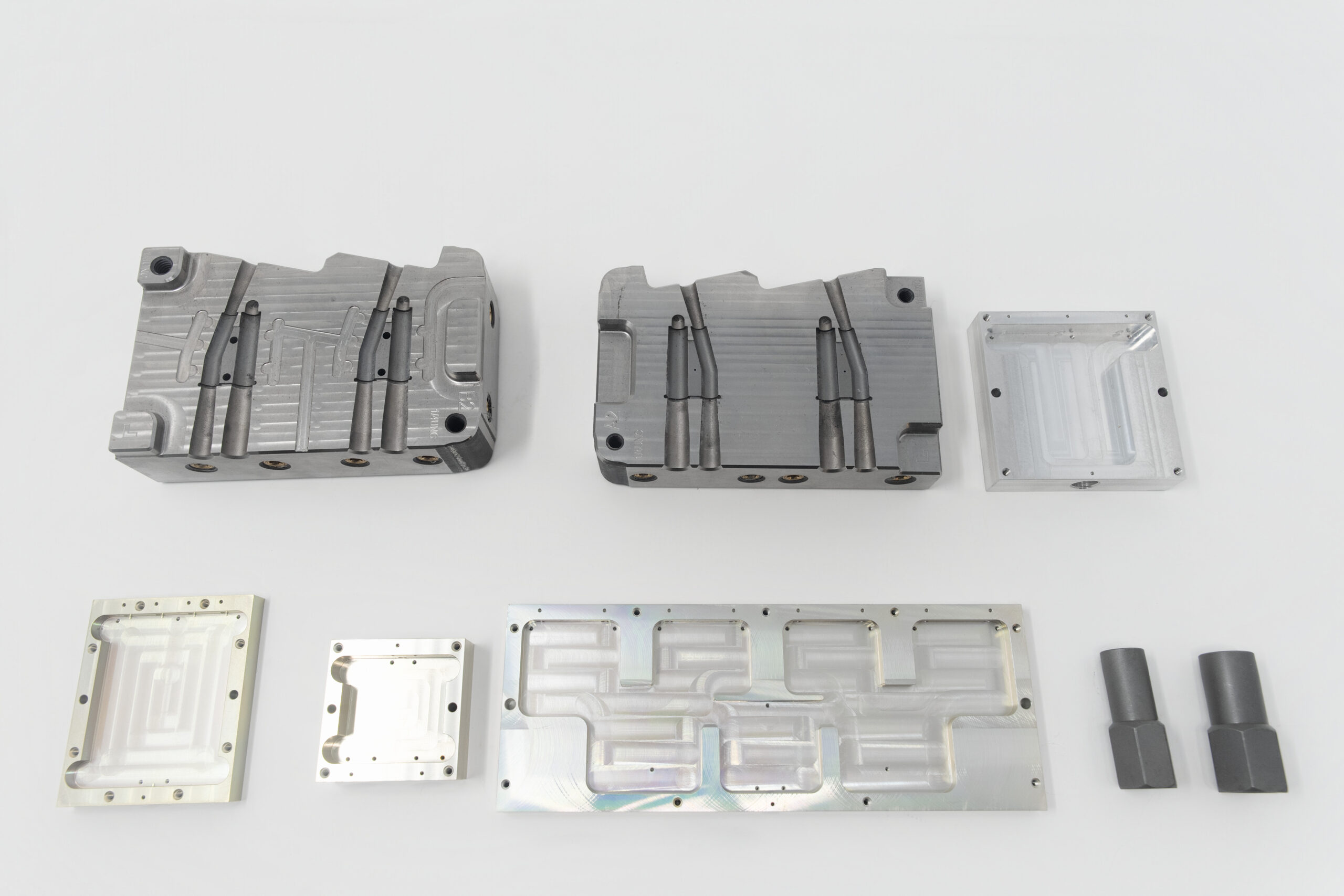

Plastic and Metal Injection Molding Specialists

Prime Manufacturing Technologies in Howard County, Maryland has been providing one stop manufacturing solutions for commercial and government clients since 1991.

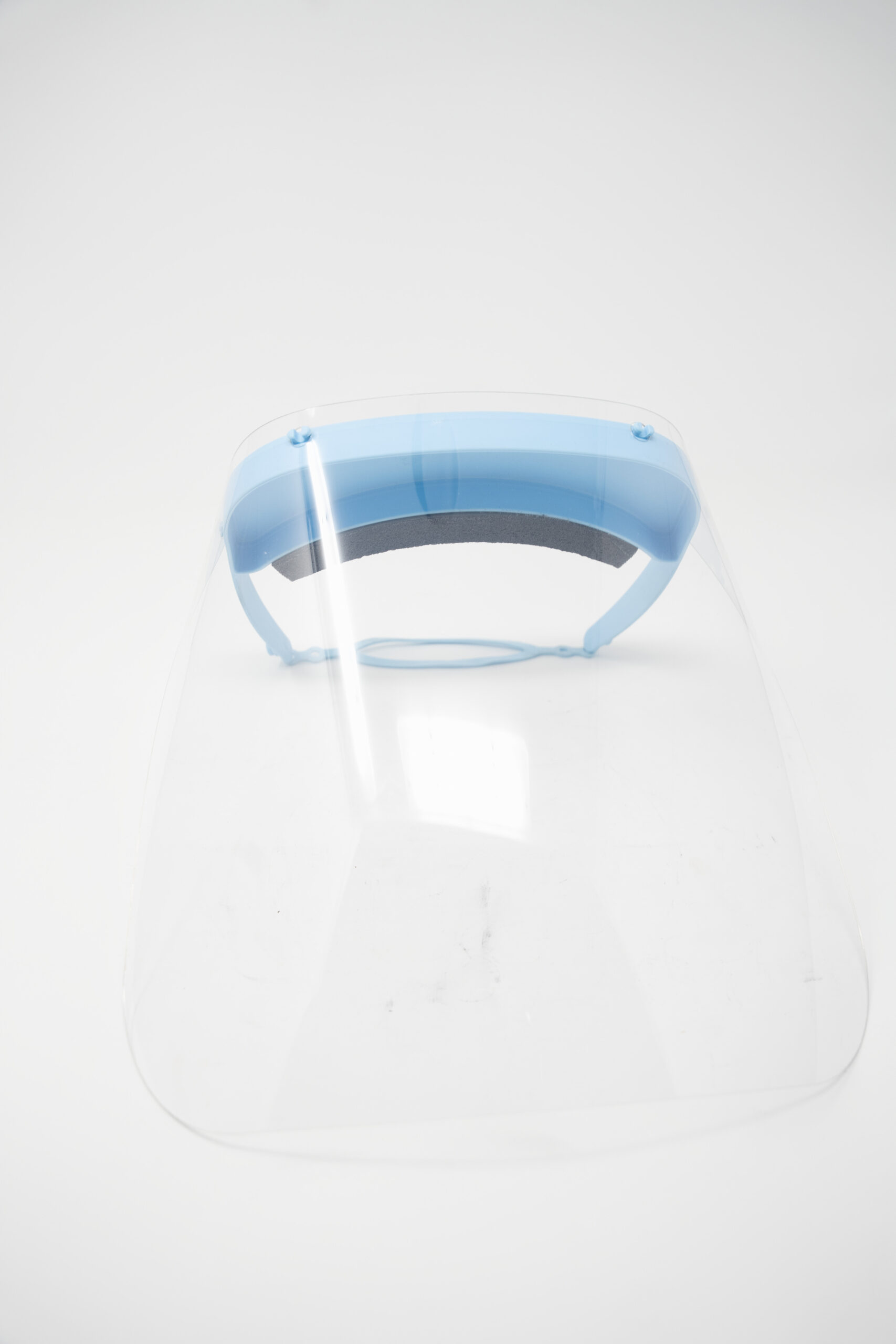

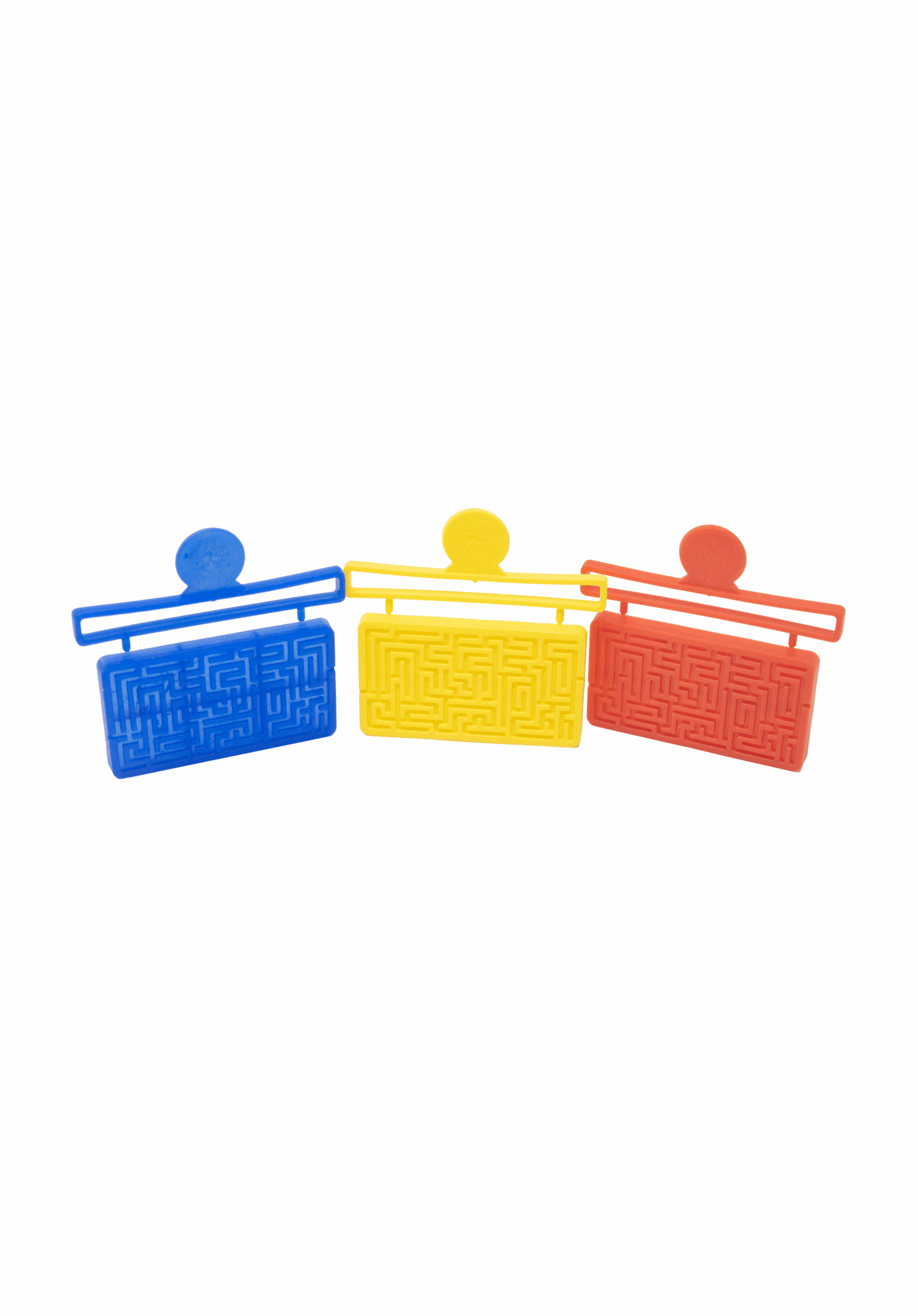

Plastic Injection Molding, Silicone Molding, Metal Injection Molding, Precision Machining, Unique Processes, and Sub-Assembly Services are some of the processes used at Prime.

From rapid prototyping to short and long run production, Prime Manufacturing Technologies has the experience and skills to handle any manufacturing and design project.

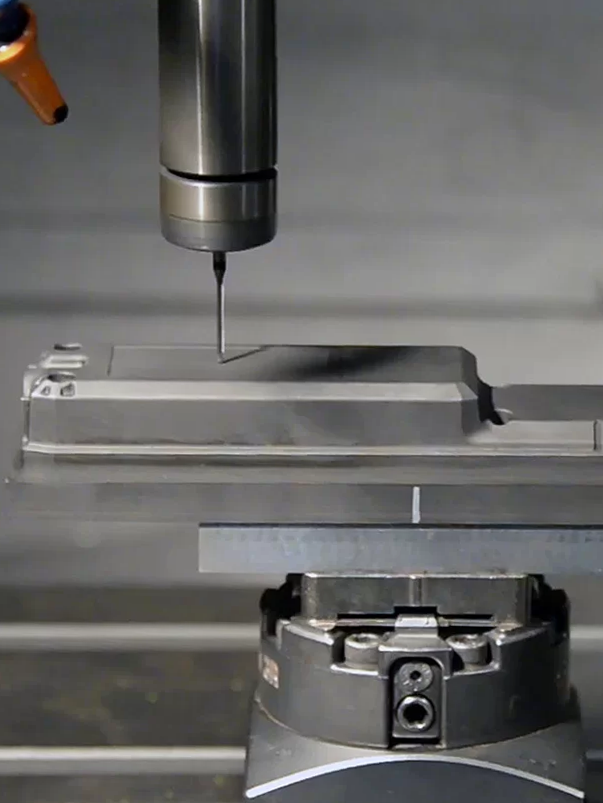

Our capabilities include Plastic Injection Molding, Metal Injection Molding (MIM), Silicone Molding, CNC Milling and Turning, CNC Electrical Discharge Machining (EDM), 6-axis robotics for assembling and casting of composite material for military parts.

Complete Design to Manufacturing Solutions

Offering the latest in digital manufacturing, design, and engineering, Prime works with clients to optimize mold design, increase product quality, improve production time and lower production costs.

When you select Prime as your manufacturing partner, you are adding a powerful, experienced, knowledgeable partner to your team – a company that can help take your business to the next level of profitability.

As a one stop shop offering assistance from design to manufacturing solutions, Prime minimizes the need for multiple suppliers, tackling your product development challenges head on with a comprehensive, results oriented approach to manufacturing and production. Best of all, we’re with you for the long haul, helping you to continuously improve your product as your business grows

Specialized Services

Molding and Machining are core capabilities at Prime. However, it is our Specialized Services, combined with hardware, software and “brainware,” that set us apart. We offer Reverse Engineering as well as specialized processes in areas of composites and silicone molding, in addition to sub-assembly services using 6-Axis robotics or other automation approaches.

We are also committed to staying current on the latest manufacturing technologies, which includes RFID tagging of parts and 3D Printing for select quick-turn needs. The application of this unique process enables us to produce injection molded parts in days, instead of the weeks as required by conventional methods.

Who We Serve

We currently serve range of companies including fortune 500 companies like Northrop Grumman (formerly Westinghouse/Gould), Agilent Technologies, Ciena, Snap-On Power Tools, and Johns Hopkins Applied Physics Lab.

Agriculture

Automotive

Construction

Department of Defense

Technology

Healthcare

Telecommunication

Contact Us

Savage, MD 20763

Phone: 301-604-0900

Email Address: [email protected]

Gallery